Products

Home/Products

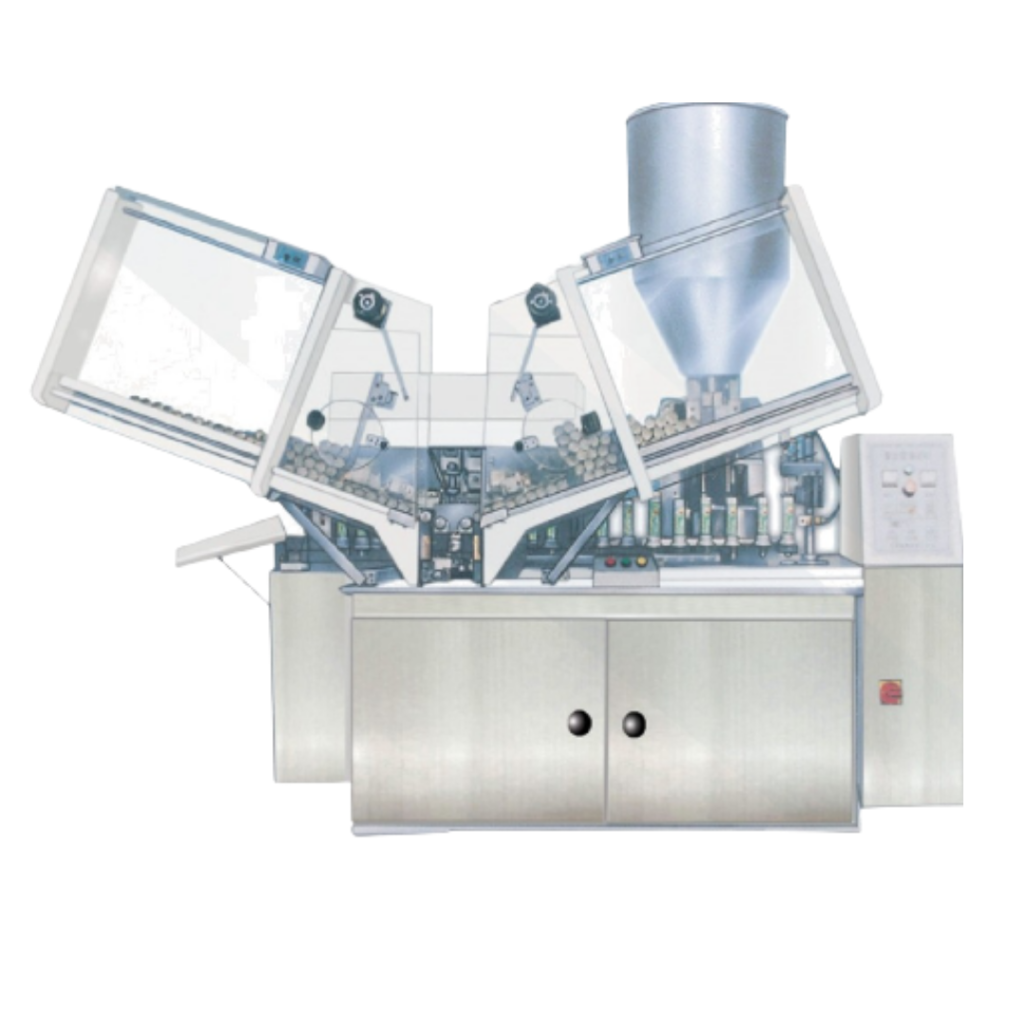

TUBE FILLER-FOR ALUMINIUM TUBES

MPTF 200/400

Suitable for filling creams, pastes,Oinments filling Sealing upto 40 to 120 tubes per minute

Magnus Fill Tube is mainly designed for filling and crimping of metal tubes. The machine can be used to fill even bottles, Jars.

The Machine can fill Pharmaceutical Ointments, shaving creams, tooth pastes, cold creams, mayonnaise

Outstanding Features

- Tubes automatically fed from inclined chutes into tube

- Correct and uniform filling with the MagnusFill system:Progressive filling while the lifted tube retreats down from the filling nozzle. This system ensures that no air is trapped during filling and also guanrantees exact filling weight and a clean closure – no paste enters the closure folds

- No tube – no Automatic disengaging of the filling mechanism when a tube is missing

- Tube ends can be folded to the pattern of your choice, with or without Standard cooding on closure within 4 figures or letters.

- All parts coming in contact with your product are rustproof and easily removable for

- Only one operator required even at maxium

- Paste not impaired – viscosity

- Filling mechanism easily adjustable to maximum output.

- Extremely accurate filling volume at each pump

- Easy cleaning of pump allows rapid change – over from one product to another

- Quick change – over from one tube size to another

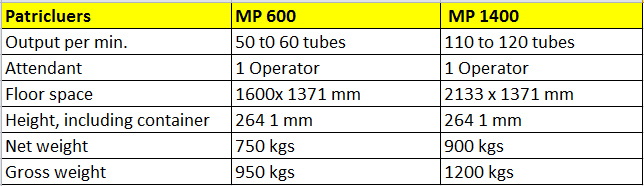

TUBE FILLER-FOR LAMI TUBES

MPFT 100

Suitable for filling creams, pastes,Oinments filling Sealing upto 40 to 120 tubes per minute

A user friendly state of art machine with logical controls makes this Magnus fiher most suitable machine for Lami tubes filling and sealing operaflon

Toothpastes,shaving creams,cold creams,ointments,colours,paints, adhesives,food pastes,syrups etc.are some of the typical products for which this machine has proved very successful.

The machine can fill ointments,pastes,creams and liquids of different viscosities for the food, cosmetics and pharmaceutical industries with

close accuracy. The product rat tail cut-off device is custom build for clean operation

Outstanding Features

- Hot air sealing system for Lami & plastic tubes

- Adaptable for Aluminium tubes

- Logical electrical controls

- GMP standard finishing

- Adequate Safety features

Optional Accessories

- Hot air sealing system for Lami & plastic tubes

- Adaptable for Aluminium tubes

- Logical electrical controls

- GMP standard finishing

- Adequate Safety features

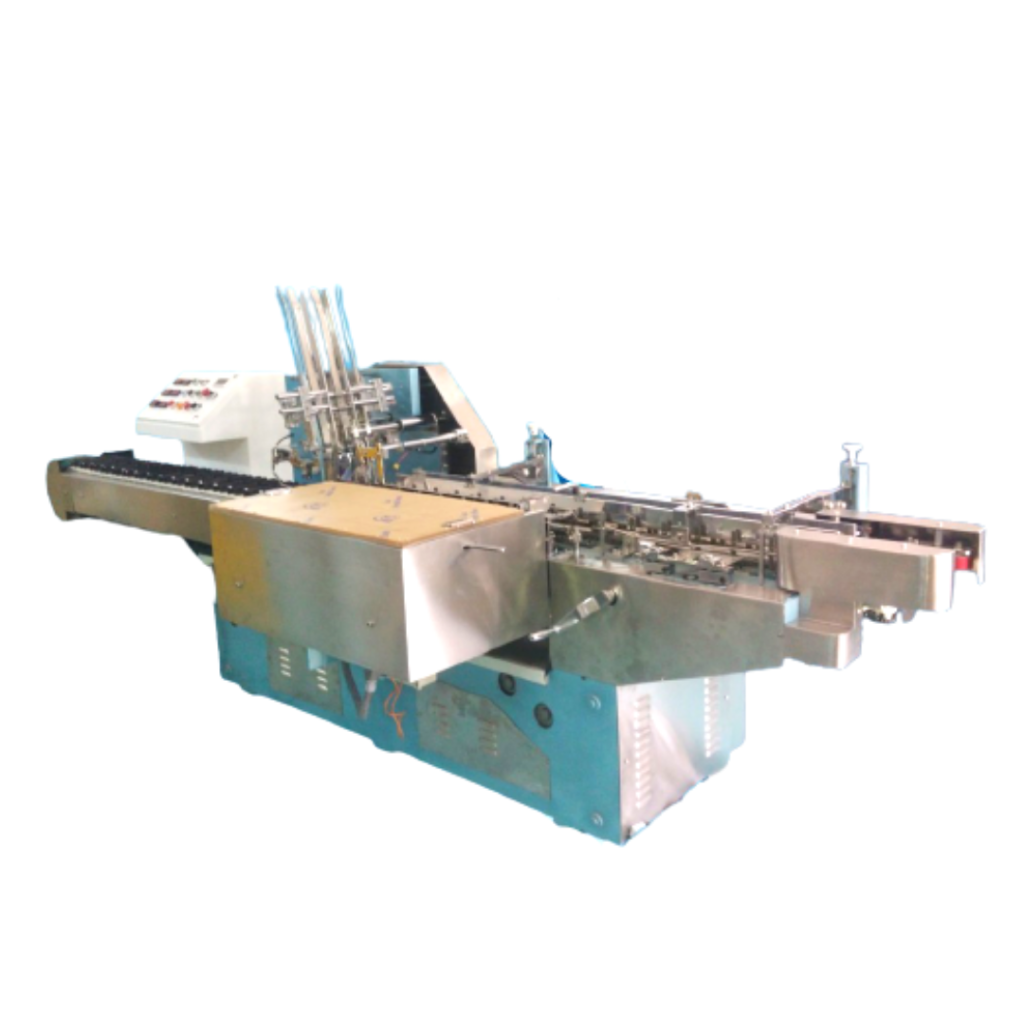

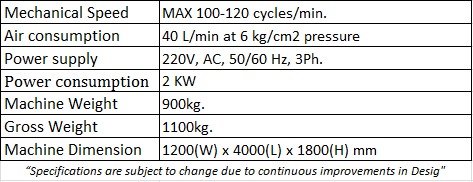

MPC-120

MAGNUS PACKAGING introduces an automatic horizontal continuous motion cartoning machine MPC100 with an output of the 100-120 Cartons per minute. Automatic Cartoning Machine — MPC100 — is a new model, based on integrated design from domestic and foreign technology, this high-tech product is incorporated with unique Mechanical, Electrical, Electronic, Pneumatic components to meet the Indian requirements. It delivers high quality performance and the best efficiency in its class. Moreover, its functioning assures impeccable steadiness and reliability at rated speeds.

Outstanding Features

- Continuous Motion Variable Speed

- Upto 100-120 cartons per minute

- Accommodates glue sealing (option) or tuck

- Straight front discharge

- No product no carton

- Separate vacuum pumps for carton pick-up

- Internationally accepted brands of Electronic & Electrical components

- Simple assembly, flexible size and speed variation.

- All the stations are laid out one after the other this ensures ease in setting and trouble free running of the machine

Optional Accessories

- Leaflet inserter

- Tube, Bottle, Pouch Or Multi ProdUct transfer device

- Batch coding device or Integration to Ink Jet

- Display for trouble Shooting SyStem (PLC touch Screen-Optional)

- Automatic counting of speed and finished packed

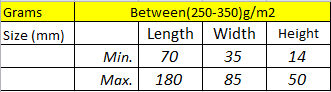

MVC-120

Magnus Packaging introduces the Vertical Cartoning Machine MVC140 with an output of up to 140 cartons per minute. The MVC140 assures high efficiency at greater speeds and provides the best quality performance when compared to other machines in the same platform. The principle of operation is as listed below.

The machine consists of fully automatic Vertical cartonafing machine. The principal of operation is as mentioned below

- End load carton is removed from a supply magazine via a reciprocating vacuum system

- Carton is erected and placed down on continuous moving chain

- Product loading into the carton can be integrated with your pick & place

- Please note, product can be comfortably, loaded in the open carton as sufficient place will be provided for 2 people on either side to load the

- Loaded carton is transported through the machine and is either tucked closed or pressed between end pressing belts

- Completed cartons are then automatically delivered from the front of the machine at a Convenient working height on an exit.

Features

- Intermittent Motion / Continuous Motion Variable Speed

- Up to 140 cartons per minute (Depend on product & carton size)

- Accommodates glue sealing(option) or tuck style closure

- Left hand load

- Straight front discharge

Carton Dimensions Range

Length: 50- 150 mm.

Height: 15- 50 mm.

Width (Fix): 25- 80 mm.

Cartons made of Good quality ITC Board or equivalent with Grain direction Perpendicular to Length, suitable automatic carton packing line.

Stranded Features

- Separate vacuum pumps for carton pick-up

- All Guards in SS sheet

- All Open-ab Ie doors be made of polly-carbon ate

- Safety as per the Industrial guidelines

Optional Accessories

Horizontal Cartoning Machine

MPC 100-120

Horizontal Cartoning Machine-MPC 100-120

Magnus Packaging introduces an automatic horizontal continuous motion cartoning machine MPC100 with an output of the 100-120 cartons per minute. Automatic Cartoning Machine – MPC100 – is a new model, based on integrated design from domestic and foreign technology, this high-tech product is incorporated with unique mechanical, electrical, electronic, pneumatic components to meet the Indian requirements. It delivers high quality performance and the best efficiency in its class. Moreover, its functioning assures impeccable steadiness and reliability at rated speeds.

MPC100 is an optimum choice for packing of Blister packs, Alu strips, Ampoule / Vial trays, Eye-drop plastic vials, Tubes, Soaps and Pouches etc. into cartons. Standard machine can handle reverse type tuck in cartons. With additional changes and gluing device it can handle glued carton also. Machine can also be linked with upstream and downstream machines for line automation.

-

Motion

Continuous motion variable speed

-

Sealing

Accommodates glue sealing (option) or tuck style closure

-

Speed

Continuous motion variable speed upto 120 cartons per minute

-

Vacuum pumps

Separate vacuum pumps for carton pick-up

-

Assembly

Simple assembly, flexible size and speed variation

-

Automation

No product, no carton

-

Components

Internationally accepted brands of Electronic & Electrical components

-

Ease of Operations

All the stations are laid out one after the other. This ensures ease in setting and trouble free running of the machine